Grip Mechatronics Pvt.Ltd. has a long history of serving the Automobile industry. We have engineered many applications for major automotive manufacturers and their ancillaries.

We provide the Automation Solutions for Designing and implementing production plants including project support, consulting and a wide range of services for following.

Auto Component Manufacturing Lines/Machines.

• Paint Shop

• Press Shop

• Special Purpose Machines

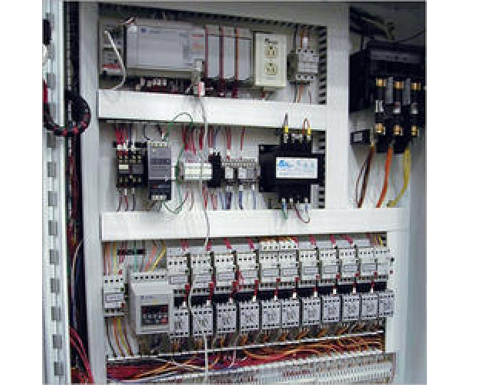

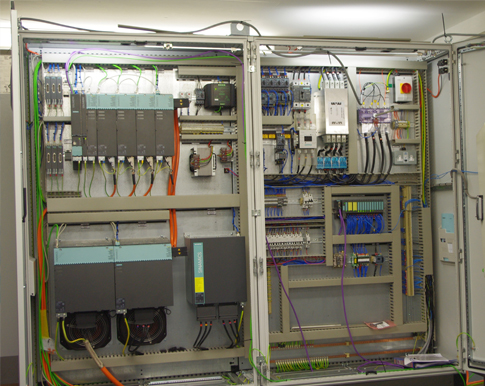

Control Panel Project

1. AMF Panel

2. MCC Panel - CUME PLC Panel

3. Control Panel

4. CNC Panel

Below are the few disciplines in which we completed projects successfully:

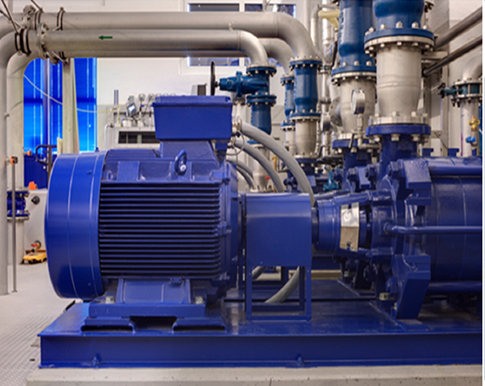

1. Cooling Tower

2. ID - FD FAN & Damper Automation

3. Hydraulic Power Packs

4. Pump House Automation

Automation & Recondition Machine Tools

M/s GRIP MECHATRONICS PVT.LTD. Is a leading in CNC and PLC / MECHANICAL services, solution, to Machine Tool Industries, Process Industries, Automobile Industries and Ancillaries and so on. To keep the manufacturing / production activities running smoothly "Accurate "offers for all services including Mechanical / Electrical / Hydraulic Service support, Mechanical and Electrical Design and maintenance.

Project Name: GKN CNC Panel

Customer Name: GKN

Project Descreption:

Computer Numerical Control (CNC) Machine Mainly Used In Mechanical Industries

Project Name: Utility PLC Motor Control Panel (Automation Project)

Customer Name: Sandvik Asia Pvt.Ltd

Project Description:

Project has 10 pumps which control by PLC or MINILEC controller and 10 motrosare dividing by in 3 part. 1st part has 4 pumps. 2nd part has 3 pumps and 3rd part has 3 pumps.

In 1st part have two pair and this two pair access by selection switch name of first part pumps is effluent pump which is control by three modes as respectively PLC mode, manual mode and MINILEC controller mode.

In 2nd part three pumps have one pair of two pumps and reaming one pump is spare.

3rd same as 2nd part but not control by MINILEC controller this part only control by PLC mode and manual mode.

NAME OF 1st PART PUMPS: EFFULANT PUMP

NAME OF 2nd PART PUMP: RETURN WATER PUMP

NAME OF 3rd PART PUMP: PRESSURE PUMP

Project Name: MAHLE leak testing machine (automation project)

Customer Name: MAHLE BHER

Project Description:

This project is base on automation. As per application we develop new machine. This type of machines used for the welding at high accuracy and bet-ter productivity.

Project Name: GANTRY CNC PANEL (MACHINE TOOLS)

Customer Name: SANDVIK ASIA PVT.LTD

Project Description:

Gantry CNC panel is used for the convery application. By using drive oper-ate the servo motor and also sensor input pp module is used.

Project Name: 2020 CNC Panel(Machine Tools)

Customer Name: TAFE

Project Description:

2020 CNC panel used for move 3 axis as respectively x axis, z axis and c axis. By this up gradation increase predictability and efficiency of machine. Servo mo-tor used for each axis .

Project Name: Up down Sheet Panel

Customer Name: MAHLE

Project Description:

By using the motor we rotate the shaft which wound the reflector sheet but we need to reduce the speed of the motor. Speed of motor reduced by the gear box